Sarah Martinez had been on the waiting list for affordable housing for three years. Every morning, she’d drive past empty lots in her neighborhood, wondering when someone would finally break ground. Last Tuesday, she took the same route to work and saw construction barriers around a familiar vacant plot. By Wednesday evening, driving home, she couldn’t believe her eyes.

A complete house stood where there had been nothing but dirt 24 hours earlier. No months of noise, no endless parade of trucks, no workers shouting over machinery. Just a finished home, ready for the next phase of construction.

This wasn’t magic. This was robot home construction, and it’s about to change everything we know about building houses.

The Machine That Builds While You Sleep

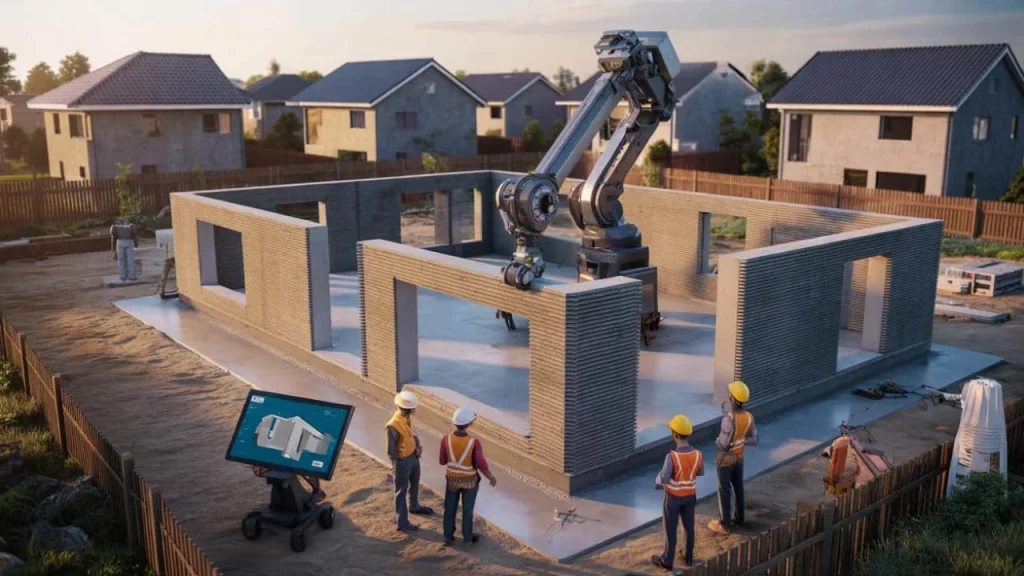

Imagine watching a house grow from the ground up in real time. That’s exactly what’s happening with the latest breakthrough in automated construction technology. These aren’t your typical construction robots—they’re sophisticated 3D printing machines designed specifically for building homes.

The process starts with a large robotic arm that moves along predetermined tracks around a building site. Instead of ink, this printer uses a specially formulated concrete mixture that hardens quickly while maintaining structural integrity. The robot follows digital blueprints with millimeter precision, extruding walls layer by layer.

“We’re seeing construction times that seemed impossible just five years ago,” says Dr. James Chen, a construction technology researcher at MIT. “What used to take six months can now happen in a single day of active printing.”

The 200-square-meter homes being produced aren’t tiny starter units either. These are full-sized family homes with multiple rooms, proper insulation channels, and spaces for electrical and plumbing systems built right into the walls during printing.

How Robot Home Construction Actually Works

The technology behind these building robots combines several advanced systems working together:

- GPS and laser guidance systems ensure the robot stays precisely on track

- Custom concrete mixtures that set quickly but remain workable during printing

- Multi-axis robotic arms that can create complex architectural features

- Real-time quality monitoring through sensors and cameras

- Weather adaptation software that adjusts printing speed and materials based on conditions

The robots don’t work completely alone. A small crew of technicians monitors the process, loads materials, and handles tasks that still require human expertise. But where traditional construction might need 15-20 workers on-site daily for months, robot home construction operates with 3-4 people overseeing the automated process.

| Construction Method | Time for 200m² Home | Workers Needed | Weather Dependency |

|---|---|---|---|

| Traditional Building | 4-6 months | 15-20 daily | High |

| Robot Construction | 24-48 hours | 3-4 supervisors | Moderate |

“The precision is incredible,” explains Maria Rodriguez, a project manager who oversees robotic construction sites. “We can build walls with integrated insulation channels, precise openings for windows and doors, and even decorative elements that would take skilled craftsmen hours to create by hand.”

Why This Could Solve the Housing Crisis

The global housing shortage affects millions of people, from young families priced out of starter homes to seniors looking to downsize affordably. Robot home construction addresses several key problems that make housing expensive and slow to build.

Labor shortages have plagued the construction industry for years. Skilled workers are retiring faster than new ones enter the field, driving up wages and slowing project timelines. Automated construction doesn’t eliminate human workers, but it reduces dependence on large crews and specialized skills for basic structural work.

Speed translates directly into cost savings. When a house can be built in days instead of months, developers save on financing costs, site security, and weather-related delays. These savings can be passed on to buyers, potentially making homeownership accessible to more families.

The consistency of robot construction also reduces waste and rework. Traditional building generates enormous amounts of material waste—lumber offcuts, excess concrete, damaged materials from weather exposure. Robotic systems use precisely calculated amounts of material with minimal waste.

“We’re looking at potential cost reductions of 30-40% compared to traditional construction,” says Tom Harrison, CEO of a European construction robotics company. “When you factor in labor savings, reduced waste, and faster completion times, the economics become very compelling.”

Real Families, Real Homes

The first families are already moving into robot-built homes. The Johnsons in Amsterdam were among the early adopters, purchasing a 3D-printed house that was completed in 120 hours of printing time spread over five days.

“Honestly, we were skeptical at first,” admits Peter Johnson. “But the walls are solid, the insulation is better than our old place, and the mortgage payment is 25% less than what we were looking at for traditionally built homes in the same neighborhood.”

These homes aren’t experimental prototypes either. They pass the same building codes and safety inspections as conventional houses. The concrete used in robotic construction often proves stronger and more durable than traditional building methods because of its consistent application and optimized mixture.

For developers, the appeal goes beyond just speed and cost. Robot home construction can work in locations where traditional building faces challenges—remote areas where transporting large crews is expensive, urban sites with limited space for equipment staging, or regions with extreme weather that limits traditional construction seasons.

What Happens Next

The technology still faces some limitations. Complex architectural features, custom finishes, and multi-story buildings require additional human expertise. Plumbing, electrical work, and interior finishing still happen the traditional way after the robotic printing completes the basic structure.

But the trajectory is clear. Multiple companies are scaling up their robotic construction capabilities, with some planning to deploy fleets of mobile printing units that can move from site to site. City planners are beginning to factor faster construction times into housing development strategies.

“We’re seeing interest from governments dealing with housing crises, disaster relief organizations, and private developers who need to build quickly and affordably,” notes Dr. Chen. “The applications extend far beyond just making houses cheaper.”

Within the next decade, robot home construction could become as common as seeing traditional building crews. The technology is moving from experimental demonstrations to commercial reality, promising to reshape how we think about housing construction, affordability, and speed.

FAQs

How strong are houses built by robots compared to traditional construction?

Robot-built homes often exceed traditional construction strength because the concrete is applied consistently without human error and uses optimized mixtures designed specifically for 3D printing.

Can robot construction work in all weather conditions?

Most systems can operate in moderate weather but may pause during heavy rain or extreme temperatures, similar to traditional concrete work.

Do robot-built homes look different from regular houses?

The basic structure may have slightly different textures, but with standard finishing work, the final appearance can be identical to traditionally built homes.

How much do robot-built homes cost compared to regular construction?

Early estimates suggest 30-40% cost savings, though final prices depend on local labor costs, materials, and finishing requirements.

Will this technology eliminate construction jobs?

Rather than eliminating jobs, robot construction shifts workers toward more skilled tasks like system operation, quality control, and specialized finishing work.

When will robot home construction be widely available?

Several companies are already offering commercial services in select markets, with broader availability expected within the next 3-5 years as the technology scales up.