Maria Santos remembers the day her engineering team first noticed the problem. Deep underwater near the Spanish coast, their expensive ocean monitoring equipment kept breaking down. The culprit wasn’t storms or saltwater corrosion—it was vibrations. Tiny whirlpools in the current were shaking their cylindrical sensors so violently that bolts loosened and circuits failed.

“We spent months trying to stop those vibrations,” Santos recalls. “Then someone asked the obvious question: what if we used them instead?”

That moment of inspiration has led to something remarkable. Spanish researchers have turned one of engineering’s most persistent headaches into a revolutionary source of turbine-free hydropower that could change how we harvest energy from rivers and oceans.

When Water Flow Becomes Your Enemy (Then Your Friend)

For decades, engineers have battled vortex-induced vibrations with the determination of someone swatting flies at a picnic. These vibrations happen when water flows around any cylindrical object—bridge pillars, underwater pipelines, oil rig supports. The water doesn’t flow smoothly around the cylinder. Instead, it creates tiny whirlpools that alternate from one side to the other, tugging and releasing in a rhythmic dance that gradually destroys everything in its path.

“Vortex-induced vibrations have probably cost the engineering industry billions in repairs and redesigns,” explains Dr. Ramon Martinez, a fluid dynamics specialist who wasn’t involved in the Spanish research. “We’ve tried everything to stop them—dampers, surface textures, complete shape changes.”

The team at Universitat Rovira i Virgili in Catalonia took the opposite approach. Instead of fighting nature, they decided to dance with it. Their turbine-free hydropower system embraces these vibrations and transforms them into electricity.

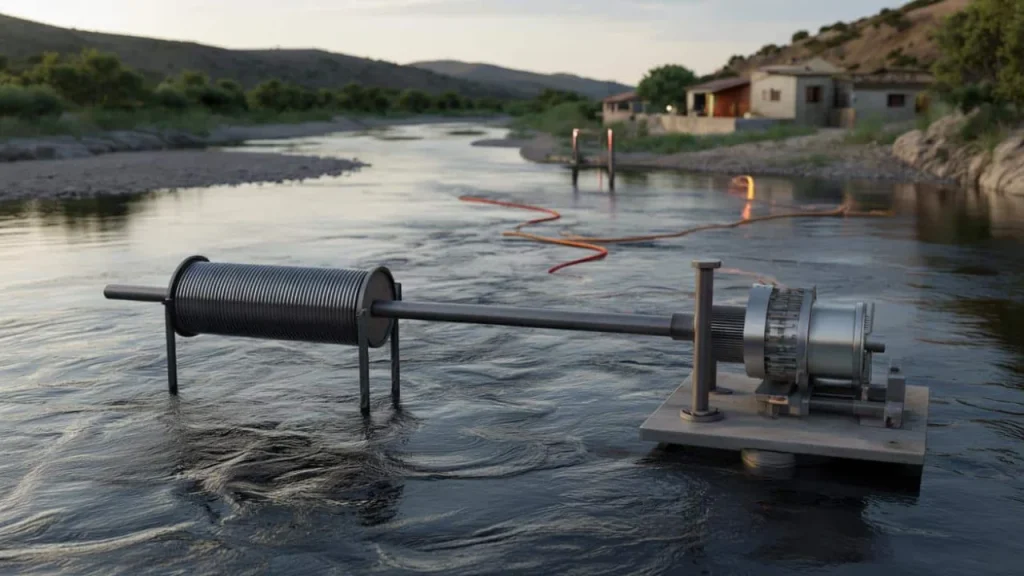

Picture a simple horizontal cylinder hanging underwater like a swing. No blades, no propellers, no complex machinery. As water flows past, those troublesome vortices make the cylinder oscillate back and forth with surprising consistency. It’s like having a submerged metronome powered by physics itself.

How Spain’s Vibrating Cylinder Actually Works

The beauty of this turbine-free hydropower technology lies in its elegant simplicity. Here’s what makes it so different from traditional underwater turbines:

| Component | Traditional Turbine | Spanish Oscillating System |

|---|---|---|

| Underwater Parts | Complex rotor, blades, bearings | Simple cylinder only |

| Moving Parts in Water | Multiple rotating elements | Single oscillating tube |

| Maintenance Access | Requires underwater intervention | Above-water platform access |

| Marine Growth Impact | Severely reduces efficiency | Minimal performance loss |

| Current Speed Needed | Higher speeds for effectiveness | Works in gentle currents |

The oscillating cylinder connects to a shaft that passes through the waterline to reach dry equipment above. Every swing of the underwater pendulum moves mechanical components safely housed on floating platforms or onshore stations. Gears amplify the motion, transmissions smooth it out, and generators convert it to electricity.

“The genius is keeping the expensive, delicate parts out of the water,” notes marine engineer Lisa Chen. “You get all the benefits of hydropower without the nightmare of underwater maintenance.”

Key advantages of this turbine-free approach include:

- No rotating blades to clog with debris or marine growth

- Gentler interaction with marine life

- Significantly reduced noise pollution underwater

- Lower maintenance costs and risks

- Effectiveness in slower water currents

- Simpler installation process

Why Traditional Underwater Turbines Keep Breaking Hearts and Budgets

Anyone who’s worked with underwater turbines knows they’re temperamental beasts. Unlike wind turbines spinning in relatively clean air, underwater turbines face constant assault from one of nature’s most corrosive environments.

Saltwater doesn’t just corrode metal—it destroys it with methodical precision. Bearings seize up. Seals fail. Sand acts like underwater sandpaper, gradually wearing away blade surfaces. Then there’s the biological warfare: barnacles, algae, and other marine organisms treat turbine blades like premium real estate, coating them until they’re barely recognizable.

“I’ve seen turbine blades so covered in marine growth they looked like underwater Christmas trees,” says offshore maintenance specialist John Torres. “Every gram of that growth kills your efficiency.”

Maintenance becomes a logistical nightmare. Every repair requires specialized vessels, weather windows, and teams of technical divers or remotely operated vehicles. A single maintenance operation can cost hundreds of thousands of dollars and take weeks to complete.

The Spanish turbine-free hydropower system sidesteps most of these problems. The underwater cylinder might collect some marine growth, but it doesn’t dramatically affect the oscillation pattern. The valuable equipment stays dry and accessible.

Who Benefits From This Vibration-Powered Revolution

This turbine-free hydropower technology opens doors for communities and industries that traditional systems couldn’t serve effectively. Remote river communities could generate electricity without massive infrastructure investments. Small island nations could harness gentle coastal currents that wouldn’t spin conventional turbines.

The environmental impact could be transformative. Traditional turbines create underwater noise that disrupts marine life communication and migration patterns. The oscillating cylinder system operates almost silently, presenting a gentler option for sensitive marine environments.

“Fish don’t seem to mind swimming around a gently swaying cylinder,” observes marine biologist Dr. Sarah Peterson. “But spinning turbine blades? That’s a different story entirely.”

Industrial applications look promising too. Coastal manufacturing facilities could supplement their power supply with these systems. Offshore platforms could use them for auxiliary power without the maintenance headaches of traditional marine turbines.

The technology scales well. Multiple cylinders can operate in arrays, creating hydropower farms that harness slow-moving river currents or tidal flows. Unlike massive dam projects that reshape entire watersheds, these installations work with existing water flows.

FAQs

How much electricity can a vibrating cylinder actually produce?

While still in development, early prototypes show promising power output comparable to small wind turbines, with the advantage of more consistent water flow than wind patterns.

Is this turbine-free hydropower system really maintenance-free?

Not completely maintenance-free, but dramatically easier to maintain since all complex components stay above water where technicians can easily access them.

Could these vibrating systems work in regular rivers, not just oceans?

Yes, rivers with steady flows are actually ideal for this technology since it works effectively even in gentle currents.

How does marine life react to these oscillating cylinders?

Early studies suggest minimal disruption to marine ecosystems since the systems operate quietly and don’t create the turbulence of spinning blades.

When might we see commercial versions of this Spanish technology?

The research team expects pilot installations within the next few years, with commercial deployment potentially following by the end of the decade.

Could this technology work alongside existing hydropower systems?

Absolutely—these systems could complement existing hydropower infrastructure or provide power in locations where traditional turbines aren’t practical.