Picture this: you’re scrolling through your phone, watching AI-generated videos that would have seemed like magic just five years ago. Every swipe, every seamless animation, every lightning-fast response depends on chips more powerful than entire computers from the past. But here’s what might blow your mind – the most critical component making all this possible comes from a company you probably associate with instant ramen seasoning.

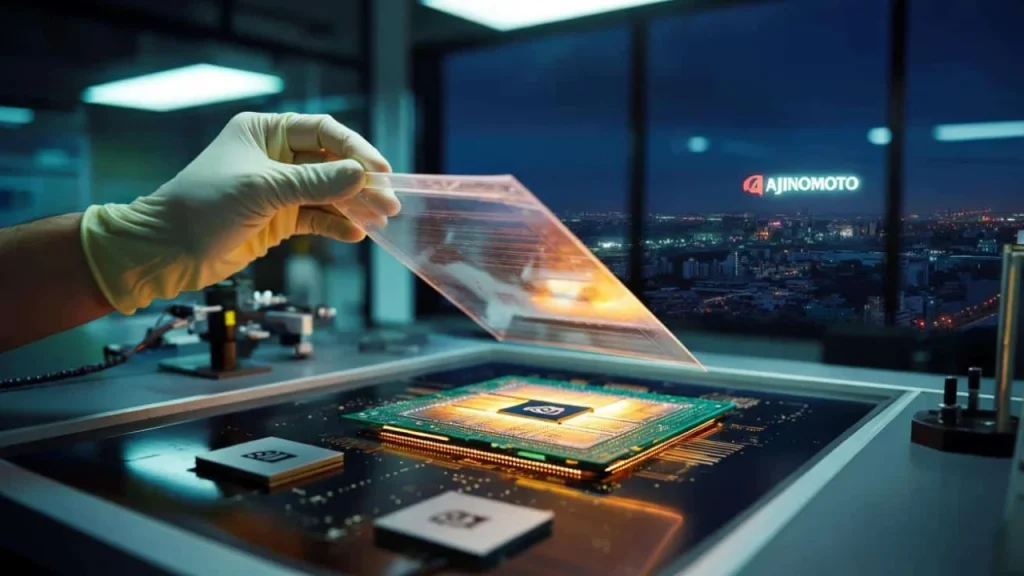

That’s right. The same Japanese company that makes the little packets of MSG in your cupboard also controls 95% of a material so crucial to modern computing that without it, the entire AI revolution would grind to a halt. Welcome to the hidden world of Ajinomoto Build-up Film, where food science meets cutting-edge technology in ways nobody saw coming.

Most people have never heard of Ajinomoto Build-up Film, yet semiconductor factories across Taiwan, the United States, and South Korea literally cannot ship their most advanced processors without it. Behind almost every cutting-edge Nvidia AI chip sits this century-old Japanese food company in an unexpected position of global power.

When Your Seasoning Company Becomes a Tech Powerhouse

Walk into any Japanese grocery store, and you’ll see Ajinomoto’s familiar logo on instant noodle packets, cooking oils, and bottles of umami seasoning. The company generates billions in annual revenue from food products, sweeteners, and additives like monosodium glutamate. But hidden deep within this consumer food empire lies a high-tech materials division that has quietly become indispensable to global chipmaking.

Ajinomoto Build-up Film, known in the industry simply as ABF, is a specialized insulating material that gets baked into the substrates holding modern CPUs and GPUs together. Think of it as the invisible foundation that prevents your smartphone from melting in your pocket or your gaming laptop from short-circuiting under pressure.

“Without ABF, you simply cannot build the high-performance chips powering today’s AI applications,” explains a semiconductor packaging expert who has worked with major chip manufacturers. “It’s not something you can easily substitute or source from multiple suppliers.”

The material works by creating ultra-thin insulating layers that allow chipmakers to pack exponentially more connections into microscopic spaces. Every time companies like Nvidia or AMD push for higher performance, they need even denser, more complex substrates – and that keeps Ajinomoto’s specialty film right at the center of the entire value chain.

The Unexpected Journey from Kitchen Chemistry to Computer Chips

The story begins in 1908, far from any semiconductor clean room. Tokyo scientist Kikunae Ikeda was puzzling over his wife’s seaweed broth, trying to understand why it had such a deep, satisfying flavor that didn’t match the four known tastes: sweet, sour, bitter, and salty.

By isolating glutamate compounds from kelp, Ikeda identified what scientists now call “umami” – often described as the fifth taste. He patented a process for producing glutamate seasoning and founded Ajinomoto in 1909, with a name meaning “the essence of taste.”

From day one, Ajinomoto focused as much on fermentation science and industrial chemistry as it did on food production. Decades of research into amino acids, fermentation byproducts, and chemical processes built a foundation of expertise that would prove invaluable in completely unexpected ways.

“The same chemical knowledge that helped them perfect MSG production gave them unique insights into polymer chemistry and materials science,” notes an industry analyst familiar with the company’s evolution. “They had capabilities that traditional electronics companies simply didn’t possess.”

The breakthrough came in the 1970s when Ajinomoto faced a costly waste problem. Manufacturing amino acids at industrial scale created huge volumes of chemical byproducts that were expensive to dispose of safely. Instead of treating this as pure waste, their research teams began investigating whether these materials could be transformed into something valuable.

Why This Little-Known Material Controls the Tech World

Here’s what makes Ajinomoto Build-up Film so critically important to modern computing:

| Function | Impact on Chip Performance |

|---|---|

| Insulation | Prevents electrical shorts in densely packed circuits |

| Heat Management | Maintains stability under extreme processing loads |

| Structural Support | Prevents warping during manufacturing and operation |

| Miniaturization | Enables smaller, more powerful chip designs |

The technical specifications tell only part of the story. ABF allows chip designers to create substrate layers measuring just micrometers thick while maintaining perfect electrical isolation between thousands of microscopic connections. Without this precision, the multi-core processors in your devices would be impossible to manufacture reliably.

Key advantages of Ajinomoto Build-up Film include:

- Exceptional thermal stability under extreme heat cycles

- Ultra-low electrical conductivity preventing signal interference

- Mechanical flexibility that prevents cracking during assembly

- Chemical resistance to manufacturing processes and environmental conditions

- Consistent quality control across massive production volumes

“When you’re dealing with chips that generate enormous amounts of heat and need to process data at incredible speeds, material reliability becomes absolutely critical,” explains a former Intel packaging engineer. “Even tiny variations in the substrate can cause complete chip failures.”

What Happens When One Company Controls Everything

Ajinomoto’s near-monopoly on advanced semiconductor substrates creates fascinating ripple effects throughout the global economy. When the company experiences production issues, major tech companies feel the impact within weeks. During the COVID-19 pandemic, even minor disruptions at Ajinomoto facilities contributed to the global chip shortage that affected everything from car manufacturing to gaming console availability.

The concentration of supply creates both opportunities and risks:

Major tech companies have tried developing alternatives or convincing other chemical manufacturers to enter the ABF market, but the technical barriers remain formidable. Creating materials that meet the exacting specifications required for cutting-edge processors demands not just advanced chemistry knowledge, but years of manufacturing experience and quality control expertise.

“You can’t just decide to start making ABF tomorrow,” notes a supply chain executive at a major semiconductor company. “The learning curve is measured in years, and even small mistakes can cost millions in failed chip batches.”

This dynamic gives Ajinomoto tremendous leverage in negotiations with chip manufacturers, even giants like TSMC and Samsung. The company has invested heavily in expanding ABF production capacity, but demand from AI chip manufacturers continues growing faster than supply can scale up.

For consumers, this hidden dependency means that a supply disruption at a single Japanese chemical plant could potentially slow down everything from iPhone production to data center expansions. It’s a reminder of how interconnected and fragile our modern technology supply chains really are.

The situation also highlights how innovation can emerge from unexpected places. While tech companies focus on processor architecture and software optimization, sometimes the most critical breakthroughs happen in seemingly unrelated industries like food chemistry.

FAQs

What exactly is Ajinomoto Build-up Film?

ABF is a specialized insulating material used in semiconductor packaging that prevents electrical shorts and heat damage in high-performance computer chips.

Why can’t other companies make similar materials?

The technical requirements are extremely demanding, and Ajinomoto has decades of specialized experience in both chemistry and semiconductor manufacturing that’s difficult to replicate quickly.

How did a food company end up controlling chip manufacturing?

Ajinomoto’s expertise in industrial chemistry and fermentation, originally developed for food production, translated perfectly to creating advanced materials for electronics.

What happens if Ajinomoto stops producing ABF?

Global production of advanced AI chips and high-performance processors would face severe disruptions, potentially affecting everything from smartphones to data centers.

Are there any alternatives to Ajinomoto Build-up Film?

While other materials exist for simpler applications, no viable alternatives currently match ABF’s performance for cutting-edge semiconductor applications.

How much does this material cost?

While specific pricing isn’t public, ABF represents a small fraction of total chip manufacturing costs but is considered irreplaceable for advanced processors.