Marie Dubois still remembers the day her electric car wouldn’t start in the dead of winter. As she waited for roadside assistance outside her home in Lyon, a neighbor mentioned something that stuck with her: “The motor in your car depends on special steel sheets thinner than paper, made hundreds of kilometers away.”

She’d never thought about it before, but those ultra-thin steel layers determine how efficiently her car’s motor converts electricity into motion. Too much energy loss, and her battery drains faster. Too little precision, and the motor struggles in cold weather.

What Marie didn’t know was that a massive industrial bet was already underway to ensure Europe could make those critical steel sheets right on home soil. And it’s happening in the windswept coastal town of Dunkirk, where €500 million is riding on the future of electric steel.

The Quiet Revolution Taking Shape in Northern France

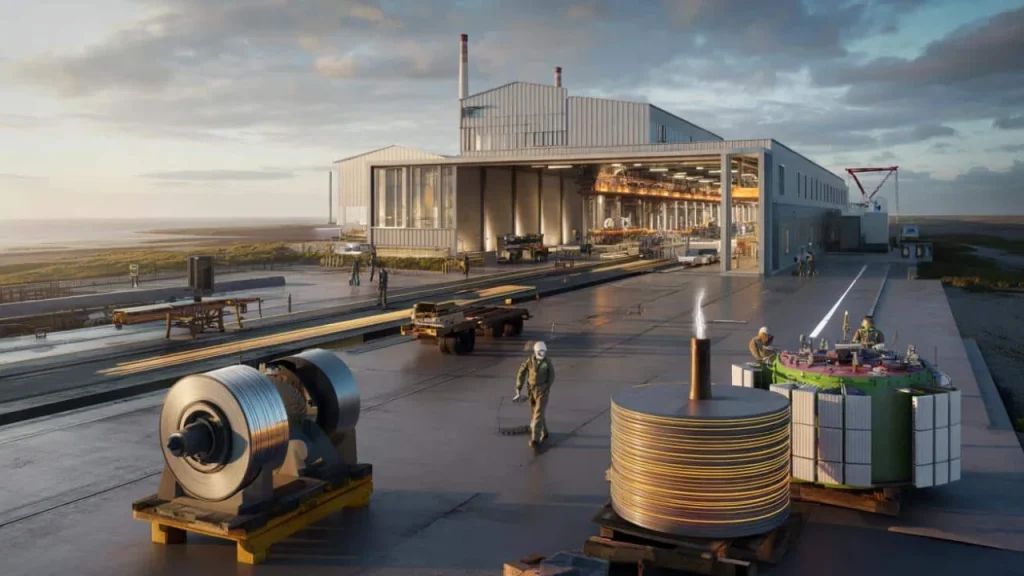

On a strip of industrial coastland near Dunkirk, steel giant ArcelorMittal is making its biggest European investment in a decade. The €500 million electric steel production facility at Mardyck doesn’t look like much from the outside—just refurbished steel halls and new equipment.

But this modest-looking project could reshape who controls the heart of Europe’s electric future. The facility will produce the ultra-precise steel sheets that sit inside every electric motor and transformer across the continent.

“Electric steel doesn’t power anything by itself, but it quietly determines how much energy gets wasted in every motor and transformer,” explains Dr. Henrik Larsen, a materials engineer who has worked with automotive manufacturers for over 15 years.

The timing couldn’t be more strategic. The global electric steel market was worth roughly €32 billion in 2023, and analysts forecast it will nearly double to €57 billion by 2032. That’s a growth rate that makes even seasoned industrial executives take notice.

ArcelorMittal’s northern France facility aims to capture a significant portion of that expanding market. Three production lines are scheduled to start operations by the end of 2025, with five lines expected to be fully operational by 2027.

Breaking Down the Electric Steel Investment

Here’s what makes this investment particularly significant for European manufacturing:

- Scale: ArcelorMittal’s largest European industrial commitment in 10 years

- Timeline: First production lines operational by late 2025

- Strategic location: Northern France provides access to both European automotive hubs and shipping routes

- Product focus: Ultra-thin steel sheets for electric motors and transformers

- Market positioning: Targeting high-value niche products rather than bulk steel

| Key Metrics | Details |

|---|---|

| Total Investment | €500 million |

| Production Lines (2025) | 3 lines operational |

| Production Lines (2027) | 5 lines operational |

| Global Market Size (2023) | €32 billion |

| Projected Market Size (2032) | €57 billion |

| Expected Growth Rate | 78% over 9 years |

The facility will focus on grain-oriented electrical steel, a highly specialized product where magnetic properties and energy efficiency matter more than raw tonnage. This represents a fundamental shift for ArcelorMittal, moving away from competing on volume toward competing on technical precision.

Why This Investment Matters Beyond Steel

For European automakers, this facility addresses a critical supply chain vulnerability. Currently, much of the world’s highest-quality electric steel comes from Asia, particularly Japan and South Korea. Having a major European production facility reduces dependence on long supply chains and potential trade disruptions.

“European car manufacturers have been increasingly worried about supply chain security for critical components,” notes automotive industry analyst Sarah Chen. “Having domestic electric steel production gives them more control and shorter lead times.”

The ripple effects extend far beyond the automotive sector. Electric steel is essential for:

- Wind turbine generators

- Industrial motors in manufacturing

- Power grid transformers

- High-speed rail systems

- Energy storage systems

France’s government views the investment as strategically crucial for the country’s green transition goals. Energy Minister Agnès Pannier-Runacher has called it “a cornerstone of French industrial sovereignty in clean technologies.”

The Technical Challenge Behind Electric Steel

Making electric steel isn’t like rolling out regular construction steel. The process requires extraordinary precision to create sheets that are often less than 0.3 millimeters thick—thinner than most business cards.

These sheets must be treated with special coatings and oriented grain structures that allow magnetic fields to flow efficiently while minimizing energy loss. Even tiny imperfections can significantly reduce motor efficiency.

“The tolerances we’re working with are incredibly tight,” explains Pierre Moreau, a metallurgist who has spent 20 years in specialty steel production. “A small variation in thickness or grain orientation can mean the difference between a motor that’s 95% efficient and one that’s 92% efficient. In electric vehicles, that efficiency gap translates directly to driving range.”

The Mardyck facility will use advanced rolling techniques and heat treatment processes to achieve these precise specifications consistently across large production runs.

What This Means for European Industry

ArcelorMittal’s investment signals a broader transformation in European steel production. Rather than competing with low-cost Asian producers on basic steel products, European companies are focusing on high-value specialty steels where technical expertise and customer relationships provide competitive advantages.

This strategy makes particular sense in electric steel, where transportation costs are relatively high compared to the product value, and where customers prefer working closely with suppliers on technical specifications.

The facility is expected to create several hundred direct jobs and support additional employment in the surrounding supply chain. For the Dunkirk region, which has faced industrial challenges in recent decades, the investment represents a significant economic boost.

Local economic development officials are optimistic about the project’s potential to attract additional investments in electric vehicle components and renewable energy equipment manufacturing.

FAQs

What exactly is electric steel?

Electric steel is ultra-thin steel sheets specially designed to efficiently conduct magnetic fields while minimizing energy loss in electric motors and transformers.

Why is ArcelorMittal investing in France specifically?

Northern France offers strategic access to European automotive markets, existing steel infrastructure, and shipping routes for both raw materials and finished products.

How will this affect electric vehicle prices?

A more stable European supply of electric steel could help reduce supply chain costs and risks, potentially contributing to more predictable EV component pricing.

When will the facility be fully operational?

Three production lines are expected by late 2025, with all five lines operational by 2027, reaching full production capacity shortly after.

What makes electric steel different from regular steel?

Electric steel requires precise grain orientation, special coatings, and extreme thickness uniformity to minimize energy losses in electrical applications.

Will this investment affect ArcelorMittal’s other European operations?

The company views this as a strategic pivot toward high-value products rather than a replacement for existing capacity, complementing rather than competing with other facilities.