Maria watched her grandfather tinker with his old watch for the hundredth time, carefully cleaning each tiny gear with a magnifying glass and tweezers. “These little teeth get clogged with dust,” he muttered, squinting at the mechanism. “One chip, one misalignment, and the whole thing stops working.” She nodded politely, but couldn’t help thinking there had to be a better way to make things spin and move together.

Turns out, Maria wasn’t the only one with that thought. In a laboratory at New York University, researchers have just proven that gears don’t need teeth at all. They’ve created liquid gears that transmit motion through fluid flow instead of metal-on-metal contact, opening up possibilities that could revolutionize everything from robotics to space exploration.

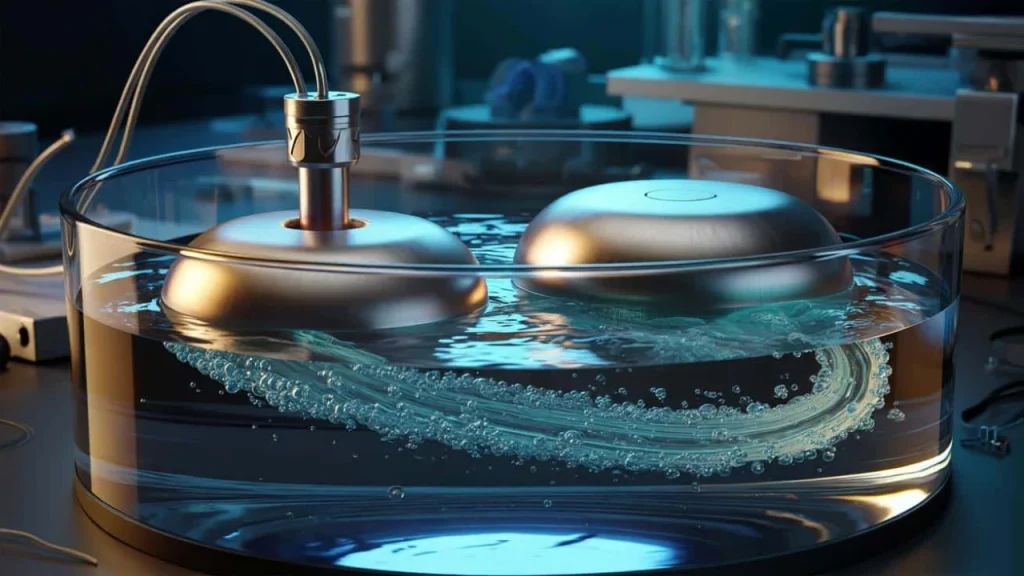

Picture this: two smooth metal cylinders sitting in a clear bath of liquid, one spinning the other without ever touching. No grinding. No wear. No maintenance headaches. Just pure, silent power transmission through carefully controlled fluid dynamics.

Why Traditional Gears Drive Engineers Crazy

Traditional gears have been humanity’s workhorses for over 3,000 years. From ancient Chinese mills to the intricate bronze Antikythera mechanism that tracked celestial movements in Greece, the concept remained unchanged: interlocking teeth that mesh together to transfer rotational motion.

But ask any mechanical engineer about gears, and you’ll hear the same complaints. Teeth wear down over time. They chip under stress. They need constant lubrication. Manufacturing requires precision machining that costs serious money, especially for high-performance applications.

“Every gear tooth is a potential failure point,” explains Dr. Sarah Chen, a mechanical systems expert not involved in the NYU research. “In space applications or deep-sea robotics, you can’t exactly pop the hood and replace a broken gear.”

The problems multiply in extreme environments. Heat makes metal expand unevenly. Cold makes lubricants thick and sluggish. Dust and debris jam between teeth. For engineers designing robots for Mars or surgical devices for human bodies, these limitations aren’t just annoying—they’re deal-breakers.

The Science Behind Contactless Power Transfer

The NYU team asked a deceptively simple question: do gear elements actually need to touch each other? Their answer came in the form of two smooth cylinders immersed in a specially formulated liquid mixture of water and glycerol.

Here’s how liquid gears work:

- One cylinder rotates, driven by a motor (the “driving” gear)

- As it spins, it drags the surrounding fluid along

- This creates swirling flow patterns in the liquid

- The flowing liquid pushes against the second cylinder

- The second cylinder starts rotating in response (the “driven” gear)

The magic happens in the fluid dynamics. By adjusting the liquid’s viscosity and density—essentially how thick and heavy it is—the researchers can control exactly how much rotational force transfers from one cylinder to the other.

| Traditional Gears | Liquid Gears |

| Metal teeth mesh together | Fluid carries rotational motion |

| Direct mechanical contact | No physical contact needed |

| High friction and wear | Minimal friction losses |

| Requires precise manufacturing | Works with smooth cylinders |

| Maintenance intensive | Self-lubricating system |

“Think of it like stirring honey with a spoon,” says Dr. Michael Rodriguez, a fluid dynamics researcher. “Move the spoon, and the honey around it moves too. Now imagine that honey movement could turn another spoon nearby.”

Where Liquid Gears Could Change Everything

The potential applications for liquid gears stretch far beyond laboratory curiosities. Industries plagued by gear maintenance costs and failures are already taking notice.

In robotics, liquid gears could enable robots that never need their joints serviced. Surgical robots operating inside human bodies could work for years without mechanical failure. Underwater exploration vehicles could dive deeper and stay submerged longer without worrying about gear corrosion.

Space applications look particularly promising. Traditional gears struggle with the extreme temperature swings and vacuum conditions of space. Liquid gears, sealed within their own contained environment, could operate reliably on Mars rovers or satellite positioning systems.

“We’re looking at transmission systems that could theoretically run forever,” notes Dr. Lisa Park, a aerospace engineering consultant. “That’s a game-changer for missions where repair isn’t an option.”

The automotive industry is watching closely too. Electric vehicle manufacturers constantly seek ways to reduce mechanical complexity and improve efficiency. Liquid gear systems could simplify drivetrains while reducing energy losses from friction.

Manufacturing equipment represents another huge opportunity. Factories running 24/7 production lines lose millions when gear failures shut down assembly systems. Self-maintaining liquid gear systems could keep production running with minimal downtime.

Even wind turbines could benefit. The massive gearboxes that convert slow blade rotation into fast generator spinning are major maintenance headaches. Liquid gear alternatives could reduce offshore maintenance costs dramatically.

The Challenges Engineers Still Need to Solve

Before liquid gears replace traditional ones in your car or phone, researchers need to tackle several engineering hurdles. The current prototypes work in controlled laboratory conditions, but real-world applications demand much more robust systems.

Temperature control presents the biggest challenge. The liquid’s properties change significantly with temperature, affecting how much torque transfers between cylinders. Hot conditions make the fluid thinner and less effective. Cold conditions can make it too thick to flow properly.

Sealing systems need major improvements too. Any liquid gear system must prevent leaks while allowing smooth rotation. Traditional seals add friction and complexity—defeating some of liquid gears’ main advantages.

“Getting the engineering details right will take time,” admits Dr. James Kumar, the lead researcher on the NYU project. “But the fundamental physics works. Now we just need to make it practical.”

Power-to-weight ratios also need work. Current liquid gear systems are heavier than equivalent traditional gears due to the fluid and containment vessel. For applications like drones or spacecraft, every ounce matters.

Cost remains another barrier. Manufacturing smooth, precisely balanced cylinders isn’t cheap. The specialized fluids add ongoing operational expenses. Traditional gear manufacturing benefits from centuries of optimization and mass production economies.

FAQs

How efficient are liquid gears compared to traditional gears?

Current prototypes show promising efficiency levels, though exact numbers depend on operating conditions. The lack of mechanical friction could eventually make them more efficient than traditional systems.

Can liquid gears handle high-torque applications?

The researchers are still testing power limits. Early results suggest liquid gears could handle significant torque, but more development is needed for heavy-duty applications.

What happens if the liquid leaks out?

Like any fluid-based system, leakage would cause failure. Engineers are working on better sealing technologies and potentially self-healing fluid systems.

How much do liquid gears cost to build?

Current prototypes are expensive research devices. Commercial viability will depend on scaling up manufacturing and reducing specialty fluid costs.

When might we see liquid gears in consumer products?

Researchers estimate at least 5-10 years for specialized applications, with broader consumer use potentially taking much longer.

Do liquid gears work in zero gravity?

This is still being studied, but the fluid dynamics principles should work in microgravity environments, making them potentially ideal for space applications.